Do you know wet pan mill gold milling machine ?

wet pan mill gold milling machine is mainly used for separation of gold, silver, lead, zinc, molybdenum, iron, copper, antimony, tungsten, tin and other minerals selected. With less investment, fast results, small footprint saving power, sturdiness and durability, ease of maintenance and high return on investment. It is the preferred production for alternative ball mill, is ideal for small and medium enterprises dressing, and high yield, low production cost, low power, and good benefits.

What is the application of wet pan mill gold milling machine ?

It is used for the material re-crushing after the first crushing. The capacity is 1-50 t/h. The maximum feed size is 30 mm, and the output size is 0.074-0.6 mm.

How to use wet pan mill gold milling machine to get gold ?

At first , you need use jaw crusher PE200X300 to crush raw gold ore , the input size usually is 200 mm ,output is about below 10 mm . After Jaw crusher , you can use wet pan mill to grinding the gold ore ,it can grind rock gold ore to be 100 -150 mesh .Due to low cost and high production efficiency, some customers from Sudan, Egypt, and South Africa would like to purchase such gold mining machines. The most exciting thing is that you can get pure gold directly after wet grinding, thus it is quite suitable for people who want to begin a small business. Finally ,you can use a shaking table to shaking the grinded gold ore to catch the gold ,the recovery can be 95 %.

what is the working principle of wet pan mill gold milling machine ?

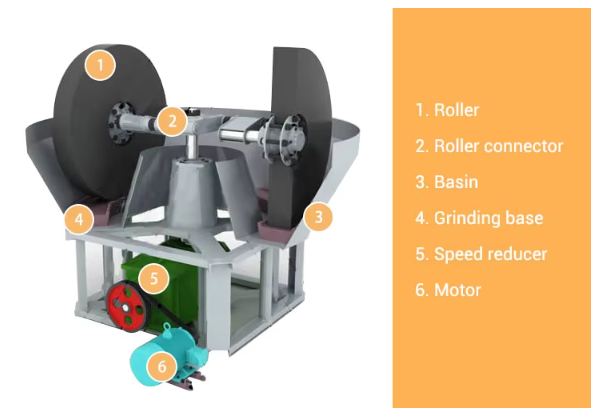

The electric motor transmits the power to the reducer. Under the drive of the reducer, the rolling wheel obtains the driving force and rotates counterclockwise along the horizontal direction of the horizontal axis.

When working, the grinding wheel can not only revolve around the large vertical shaft of the wet mill, but also rotate around the central axis of the grinding wheel, while the grinding plate is fixed. The added ore material is subjected to squeezing force from the weight of the wheel in the mill, and the huge friction force generated by the wheel during rotation and rotation of the wheel and the grinding disc is completely crushed after repeated extrusion, kneading and grinding.

what is the recovery of wet pan mill gold milling machine ?

Wet pan mill can grinding the gold ore from 30 mm to be 100-150 mesh one time ,the grinding efficieny is about 90 % ,after gring the wet pan mill usually go with shaking table or gold concentrator

The shaking table is a gold concentration machine. It enjoys a high gold recovery rate, up to 95%.

Some of our African customers from Uganda, Tanzania, Zimbabwe, Kenya, prefer to combine a wet pam mill with a shaking table to separate rock gold ore.

If wet pan mill with gold concentrator the recovery can be as high as 90%, especially for the case in recovering the natural gold in lode ore with 65% of the ore having a milling size of 0. 074 mm, the recovery for the natural gold is expected up to 98%, For that natural gold of 0.004 mm in particle size, the recovery is 97%. The cleaning up cycle is 1~4 hours, and the upgrade ratio is up to 1,000 times.

What is cost of wet pan mill for gold ore ?

Wet Pan Mill costs less than that of a ball mill, and also less than that of similar pan mills in the market. Our price is as low as $3900.

High grinding efficiency. The production capacity is up to 50 tons per hour.

The grinding is uniform, and the output size is as small as 0.074 mm.

Low noise, low energy consumption, and safe operation.

Easy to operate and maintain.

The grinding roller is more wear-resistant. And the whole machine is made of high-manganese alloy steel, which has a longer service life.