what is wood chipper?Application scope:Widely used in mushroom material crushers, various strain material crushers, the preparation sections of industries such as papermaking, edible fungi, machine - made charcoal, particleboard, sawdust board, high - density board, medium - density fiberboard, and

what is wood chipper?

Application scope:

Widely used in mushroom material crushers, various strain material crushers, the preparation sections of industries such as papermaking, edible fungi, machine - made charcoal, particleboard, sawdust board, high - density board, medium - density fiberboard, and single wood flour (sawdust) bases. The cutting raw materials are mainly logs and branches.

Introduction:

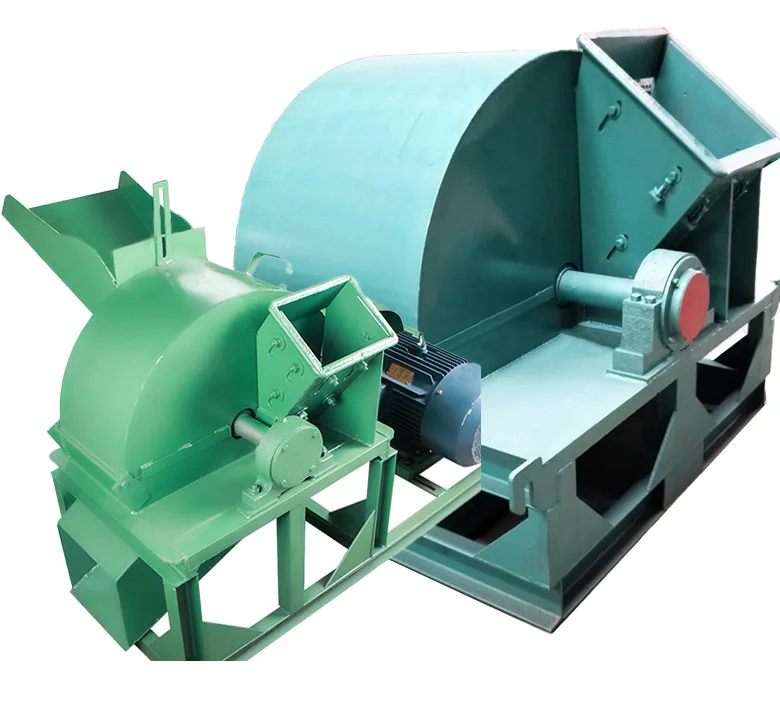

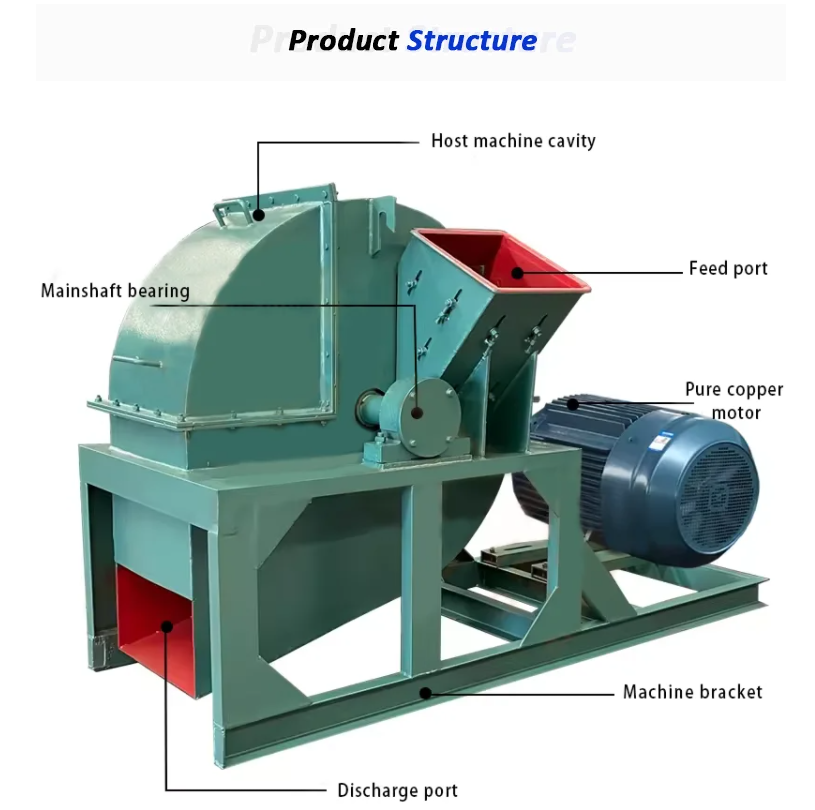

The wood chip crusher, also known as the mushroom material crusher, sawdust crusher, and sawdust machine, is a series of special - purpose wood - crushing equipment invented after years of design to meet the needs of China's industries. It integrates slicing and crushing functions. It can cut branches and trunks with a diameter of 1 - 20 centimeters, and can also be used for cutting fibrous stalk - like materials such as bamboo, thatch, corn stalks, and sorghum stalks.

What are the applicable materials for the wood chipper?

It is mainly used for processing materials such as tree branches, wood chips, waste materials, wood boards, and raw bamboo. At the same time, this equipment can also be used for cutting and shredding fibrous stalk-like materials such as bamboo, thatch, corn stalks, and sorghum stalks.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

What is the principle of the wood chipper?

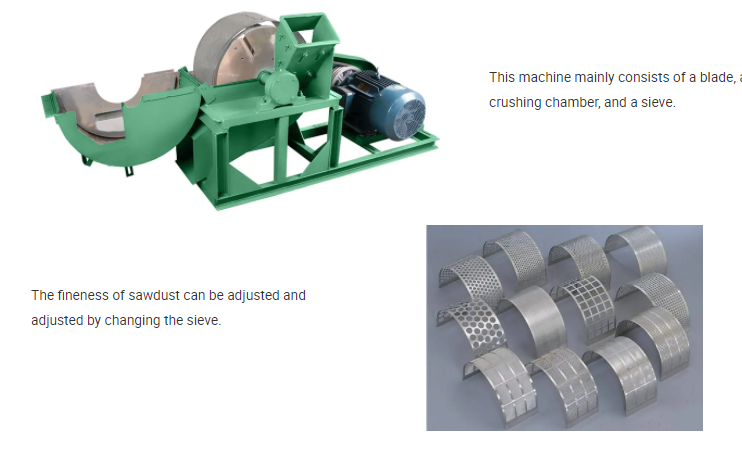

The wood chip shredder integrates blade cutting and high-speed airflow impact, achieving dual shredding functions and simultaneously completing the micro-particle sorting process. During the blade cutting and shredding process, the rotor generates high-speed airflow, rotating in the same direction as the blade cutting. The material is accelerated in the airflow and repeatedly impacted, causing the material to be shredded simultaneously, thus accelerating the shredding rate.

*The output will vary according to different materials, feed particle size and other factors